Minimum Bending Radius

The minimum bending radius is the smallest possible bending radius of materials without breaking the workpiece. How much a plate can be bent depends on several factors. The type of material and the material thickness play an important role. Otherwise damage can occur, as shown in this picture.

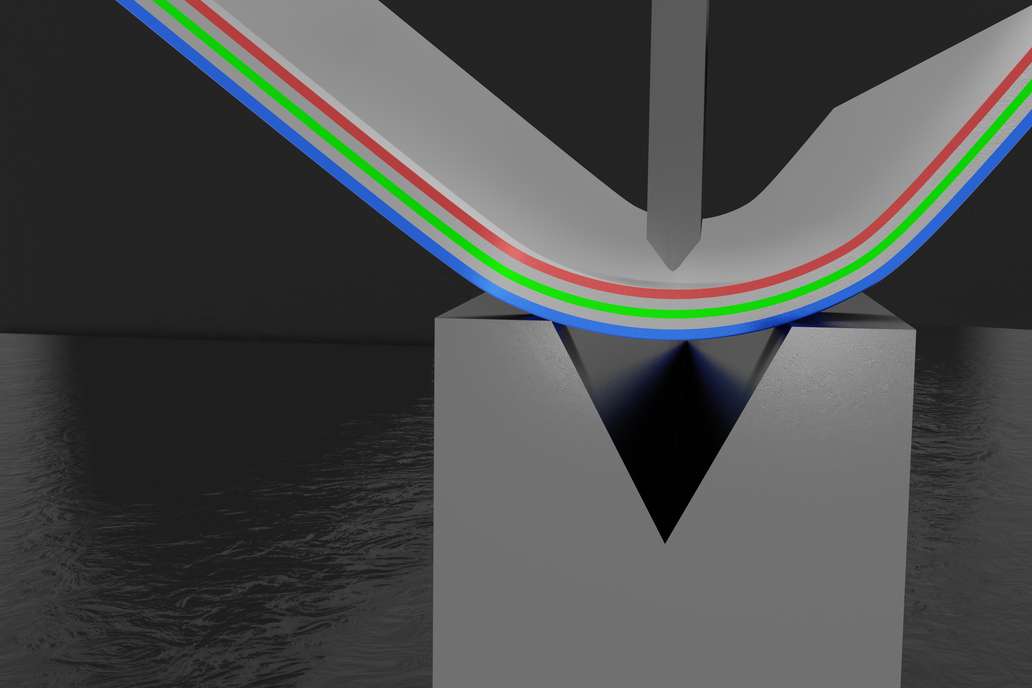

During the bending process the outer fibres (blue), i.e. the outside of the bent part, are stretched. The inner fibres (red), the inside of the bent part, are compressed.

Between the outer and inner fibres there are neutral fibres, which are marked green in the figure.

This area is neither stretched nor compressed. Minimum bending radii must be adhered to in order to prevent quality losses caused by stretching and compression. If the bending radius is smaller than this minimum value, cracks form on the outside, crushing (pinches) on the inside and the cross-section changes in the bending zone. There is therefore a risk of the workpiece breaking.

Various factors are important to determine the minimum bending radius, for example:

- Sheet/plate thickness

- Material strength

- Material

- Tools

- Bending speed

- Machine

- Bending method

- Grain/direction of rolling

Each material to be worked also has its own conversion factor. For example, the minimum bending radius of aluminium is determined by multiplying the sheet thickness by a factor of 2. If copper has to be bent a factor of 1.5 must be used. For steel the factor is 1. In this case the minimum radius equals the respective sheet thickness.

As the extensibility (ductility) of harder steels is lower than that of softer steels, the minimum bending radius of materials with high strength is also larger than for less strong steel grades. Although trial bending is carried out to determine the truly precise minimum bending radius. The values obtained in this way are kept in tables, which must be accessible for everyone involved in this operation (including the preparation phase).

The effect of the rolling direction

Another important factor is the rolling or grain direction. The stretching of material during rolling creates a fibrous material microstructure. The elongation (strain) of the fibres always sets in in the direction of rolling. If the sheet or plate is bent lengthwise in the rolling direction, the material can tear open. The minimum bending radius must therefore be larger. Bending across the rolling direction is the better variant and enables a smaller minimum bending radius.

Bending radii and bending radius

We have four press brakes with dimensions 3,500 mm, 6,000 mm 8,000 mm and 16,000 mm. On these press brakes we can use radius dies to bend high-precision inside radii. Radius stamps have to be used if extremely resistant steel grades, for example HARDOX wear plate , are to be bent. These materials are very hard, but tend to tear if the inside radii are too small.

With our radius dies and stamps we ensure that materials are bent optimally according to their specific properties, without losing their stability.

Spring back

If a workpiece is to be bent with a specific angle, it must be bent beyond this angle, because the workpiece springs back slightly after bending. The spring back can be compensated well with modern CNC press brakes.

It only becomes critical if a metal sheet is to be bent with precisely its minimum bending radius at a given angle, as the spring back means that the bending angle must be higher than the minimum angle given with that radius. For this reason the actual minimum bending radius must always be larger than the theoretical possible radius at the given angle on the datasheet.

See also

Brinell hardness test

Performing the hardness test by means of a ball pressure test according to the Swedish engineer Johann August Brinell.

Read moreCoil

Plate metal that is rolled-up to coils is easier to transport and requires less space in the warehouse

Read moreCorrosion

Corrosion is a natural process and damages most metals. What types of corrosion are there?

Read more