Weathering steel

A rusty nail, the black layer on a silver ring or the green coating on a copper coin - rust and corrosion is everywhere! In some cases, an oxygen-tight layer develops which protects the underlying material, as is the case with rustproof steel and aluminium.

Rust, corrosion, oxidation

Corrosion often leads to major problems when it attacks steel bridges or other structures. Every year several billions are spent on corrosion protection and other corrosion-related issues.

Corrosion is the chemical reaction between two substances, at least one of which is a metal, in which an exchange of electrons takes place. Rust is the same as corrosion, but only with steel products this is called rust. The transformation usually involves a reaction with oxygen in which the pure metal is converted into a chemically more stable metal oxide.

The term "oxidation" is also frequently used and suggests that it is always a reaction with oxygen. However, this is not always the case, the term oxidation is now used for all chemical reactions in which electrons are exchanged.

For example, this often happens in a battery or accumulator and is called a reductive oxidation reaction.

What is Weathering steel?

Since man has been processing iron, corrosion and effective corrosion protection have played a role. Among other things, it is applied in such a way that the oxide layer becomes so dense that it no longer allows oxygen to pass through to the underlying material, which stops the oxidation process. A good example of this is rust resistant steel, in which chromium reacts with oxygen to form chromium oxides, which provide the surface with the oxygen-tight layer. The disadvantage is that the combination of chromium and the widely used nickel in stainless steel leads to high material prices.

Already in 1932, the inventor Byramji D. Saklatwalla developed a steel variant that produced an oxygen-tight surface. This variant was further developed by United Steel Corporation and named COR-TEN steel. This is an abbreviation for "CORrosion-resistant" and "TENsile strength". Weather-resistant steel is a low-alloy steel consisting of iron to which small amounts of copper, phosphorus, silicon, nickel and chromium have been added. The tensile strength (yield strength) of the material is approximately 355MPA (N/mm²). Corten is therefore a brand name for Weathering steel, which is only supplied by U.S. Steel Corporation.

The surface of weather-resistant steel rusts just like normal structural steel. But an oxide layer is formed, which is so dense that oxygen can no longer intrude.

The use of weathering steel

Weathering steel is used relatively frequently for works of art and is therefore also referred to as "artists' steel".

It is also used in sea containers, constructions such as bridges and chimneys. Weathering steel is increasingly being used in architecture as roofing or cladding in recent years. They are also regularly seen as noise barriers along motorways.

In addition, the material is often found in various garden products such as borders and flower boxes, fences, fence panels or garden doors. Fire baskets and garden fireplaces are also often made of Weathering steel. The heat causes the steel to oxidise more quickly and reach its rusty surface faster. Because of the rust resistance, such objects can often be enjoyed for a long time.

Issues to be considered in design and construction

- Weathering steel surfaces do not allow oxygen to pass through, but can still wear out. This can be caused by acid rain, hail or the abrasive effect of sand. This exposes the underlying material and the oxidation process starts again. Weathering steel can therefore rust through over a longer period of time. A salty environment (use in coastal areas or places where salt is used in winter) also leads to a degradation of the patina layer.

- Weathering steel needs to be alternately wet and dry to produce a good corrosion layer. If the steel remains permanently wet, it will eventually rust through. During the design and also during the later construction it must therefore be ensured that there are no cavities in which water can remain. Wet leaves can also cause problems if they remain on the material.

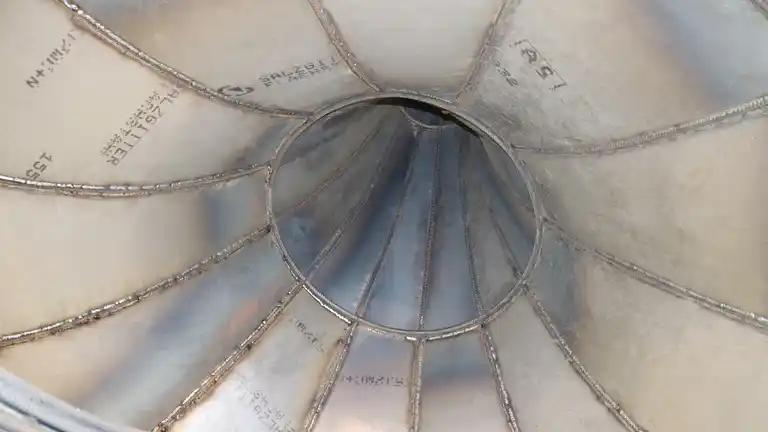

- Welding weathering steel requires additives that are identical to the weathering steel itself. This means that this filler metal is not stronger than the base material. This is a significant difference from the additives used for welding structural steels. In addition, the weld seams must be smooth to prevent water from entering cavities or gaps.

- Fasteners, such as screws or bolts, should be made of Weathering steel, which is generally not easily available. Alternatively, fasteners made of rustproof steel can be used, but this makes them more expensive to process.

- During the rusting process, rainwater running off may cause rust stains on underlying materials. This rusting process can last for several months.

See also

BRINAR

BRINAR is a wear-resistant steel which is used in mechanically highly stressed areas.

Read moreConstruction Steel

Construction steel has excellent mechanical properties and can be processed very well.

Read moreCopper

Copper is used in many ways for industrial and construction purposes. It is also suitable as an alloying element.

Read more