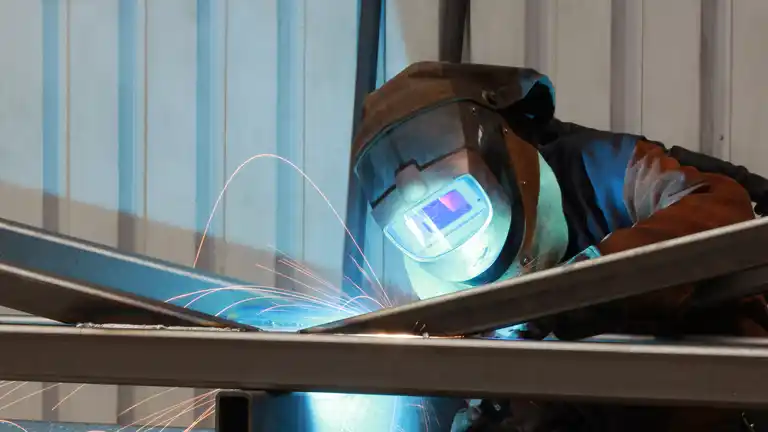

Welding

Rime GmbH is a certified specialist welding company. We use various welding processes such as MIG, MAG, WIG as well as spot and stud welding. Equipment and components for metal, machine and vehicle construction as well as for pipeline, plant and steel construction can be manufactured by us in accordance with DIN EN 3834-3.

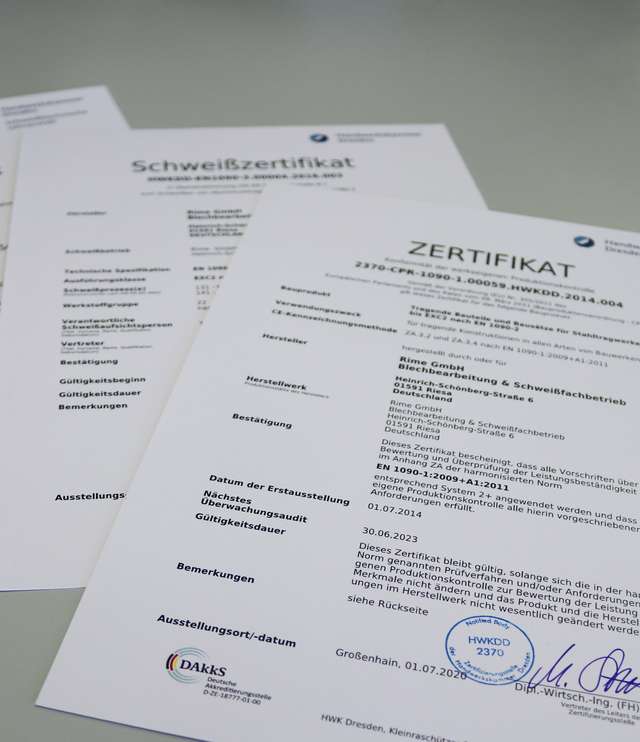

Certified welding company

We are certified in accordance with EN 1090-2 EXC 2 and EN 1090-3 EXC 2 and fulfill all requirements for the welding and construction of load-bearing steel and aluminum components. We have a wide range of processing possibilities and can manufacture individual parts required for welding assemblies in-house. We use various welding processes such as MIG, MAG, TIG as well as spot and stud welding.

Contact us!

Call or write us an email if you have questions about welding or need a quote!