Elements

Chemical elements play a major role in steel production. On the one hand, they already occur naturally in iron ores as accompanying elements, on the other hand they are added to the steel melt as alloying elements. In this way, steel grades with different properties can be produced.

Accompanying elements

Accompanying elements are all the elements that occur naturally in steel alloys. Some by-elements are harmless, but other elements can negatively influence the mechanical properties of steel. In steel production, the composition of the alloy must be precisely maintained in order to obtain desired properties.

Harmful accompanying elements (steel pests) are removed from the alloy and alloying elements are added if certain material properties are desired.

Steel pests

- Arsenic

- Antimony

- Hydrogen

- Phosphorus

- Oxygen

- Tin

Alloying elements

- Carbon

- Chromium

- Manganese

- Nickel

- Vanadium

Other accompanying elements can have both negative and positive effects on an alloy. A prime example is nitrogen, which has a detrimental effect on toughness but improves strength in austenitic steels and increases the hardness of surfaces by nitriding.

The percentage by mass of by-elements is standardised for each steel grade.

Alloying elements

The properties of metals can be changed by adding alloying elements. With a few exceptions, these elements are metallic and have various effects on the base material. With the alloying elements, a distinction is made as to whether they form carbide, austenite or ferrite in the steel and which effect is to be achieved by the addition. The strength of the influence also varies.

Example

This becomes clear, for example, with the alloying elements tungsten and silicon and their effect on steel:

Tungsten

- Strong improvement of wear resistance

- No influence on elasticity

Silicon

- Strong degradation of wear resistance

- Strong improvement in elasticity

This example impressively shows how complex the influence of alloying elements can be. The improvement of one property can result in the deterioration of another property. In steel production, the elements that improve the properties for the subsequent use of the steel are added. For example, there are wear-resistant steels, steels resistant to salt water and acids, and also steels that can withstand radioactive radiation.

Adding the alloying elements only creates the preconditions for the change in properties. Only further processing steps, such as heat treatment, lead to the desired changes in the steel structure and thus also to the desired result.

Besides carbon, these are the most important alloying elements:

- Aluminium

- Beryllium

- Chromium

- Cobalt

- Copper

- Manganese

- Molybdenum

- Nickel

- Niobium

- Silicon

- Nitrogen

- Tantalum

- Titanium

- Vanadium

- Tungsten

Aluminium

Aluminium is about 50 % lighter than iron due to its low density. The low weight makes this material very interesting for constructions in vehicle and aircraft construction that do not weigh much but still have a high degree of stability. Aluminium sheet is not only light, it is also a fairly soft metal that is excellent for forming and machining.

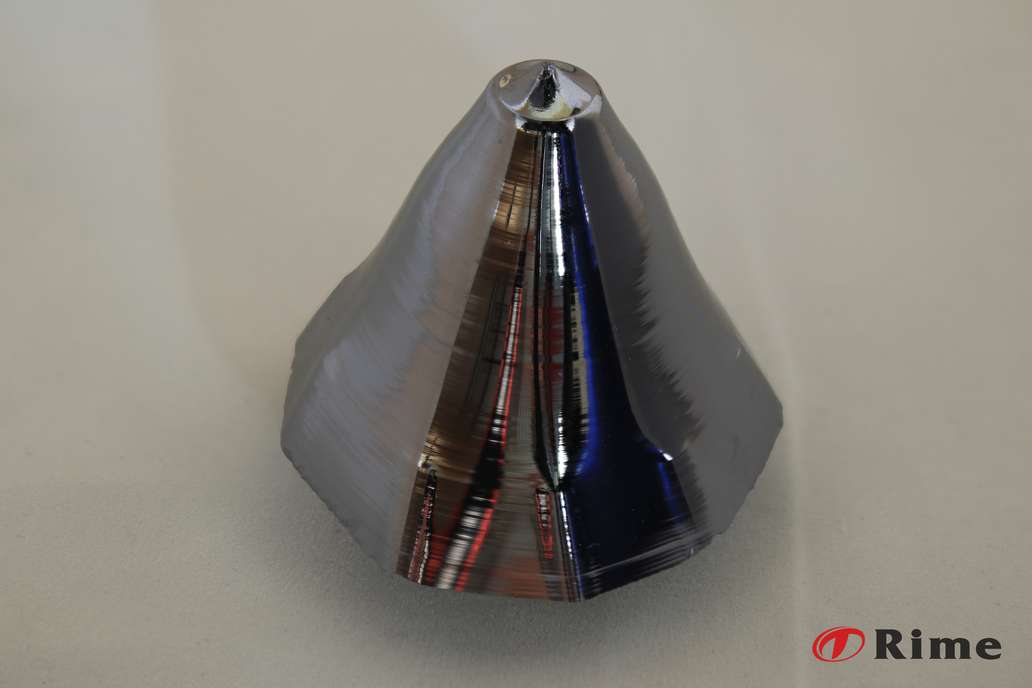

Despite these properties, aluminium sheets are very stiff and give constructions a high degree of stability. Aluminium sheets are regularly processed at Rime.

Aluminium as an alloying element

Aluminium is also used as an alloying element in steel production. Aluminium and nitrogen form nitrides, which increase the hardness of nitriding steels. It also improves the formation of fine grains.

Trivia

Aluminium is extracted from the ore bauxite and does not occur in pure form in nature. Because of its complicated production, aluminium was more valuable than gold 150 years ago. The royal houses were crazy about it. Napoleon III of France had a set of aluminium cutlery with which only he and selected guests were allowed to dine. The other guests had to be content with knives and forks made of gold. At that time, aluminium was also cast into ingots and stored in treasuries.

Lead

Lead is a heavy metal and has been used by humans for thousands of years. The Romans used it to make water pipes and sweetened their wine with lead(II) acetate. Today it is used, among other things, to shield radiation and in electrical engineering. Lead is suitable as an alloying element if it is added in the small amount of maximum 0.5%.

Lead improves machinability and is mainly used for free-cutting steels. The addition of lead increases the process reliability and shorter chips are formed. This improves the quality of the cut surfaces. Despite the low Mohs hardness of 1.5 and the low melting point of around 328°C, lead does not affect other mechanical properties of steel.

Directive on the prohibited use of lead, mercury, cadmium and hexavalent chromium

In 2005, the use of the above-mentioned elements was re-evaluated due to their hazardous effects on health. In the process, lead as an alloying element was also very strongly restricted in the EU and limited to 0.1 percent by weight. There are only a few exceptions where the limit may be exceeded.

These materials are exempt from the ban as long as a higher lead content is unavoidable. Through intensive material research, progress has now been made in the production of lead-free steels, which nevertheless exhibit very good machining behaviour. As supplied, lead-alloyed steel does not pose a health risk because the element is firmly bound in the steel and cannot be inhaled, swallowed or absorbed through the skin. Suitable protective measures must be taken during processing to avert health hazards.

Chrome

Chromium is used in electroplating for bright, hard and black chromium plating, as a catalyst in the chemical industry, but also in steel production. Chromium is one of the most important alloying elements for the production of corrosion- and heat-resistant steels. Chromium is one of the most important alloying elements for the production of corrosion- and heat-resistant steels.

Chromium additions make steel oil- or air-hardenable. Chromium is a carbide former in alloys. These carbides significantly increase cutting resistance, wear resistance and heat resistance. To achieve corrosion resistance, at least 13% chromium must be added to the steel.

Trivia

The French chemist and pharmacist Louis-Nicolas Vauquelin discovered the element as early as 1798. It was called chromium because of the multicolour of its salts. Traces of the element can also be found in precious stones such as rubies and emeralds. In the 19th century, it was mainly used for colour pigments and in tanning for leather production. One of the best-known pigments is chrome yellow, the colour used by Deutsche Post.

Cobalt

Cobalt is a rare transition metal that mainly occurs only in combination with other elements. It is usually extracted from copper and nickel ores. In the past, cobalt was mainly used for the production of colour pigments. Today, this element is used, among other things, in rechargeable batteries and as an alloying element. Steels alloyed with cobalt have an enormously high wear resistance and retain their strength even at high temperatures. For this reason, cobalt steels are suitable for components that have to withstand particularly heavy loads, such as engine and turbine components.

Trivia

In the Middle Ages, cobalt ores were often confused with silver ores. However, cobalt ores usually also contain sulphur and arsenic compounds, which caused bad smells during smelting. The miners believed that cobolites had eaten up the valuable silver and left behind the low-value cobalt instead.

The chemist Georg Brandt discovered the metal in 1735 while experimenting with "goblin ore". Inspired by this medieval story, he gave the metal the name cobalt.

Carbon

Carbon occurs in nature in pure form as diamond or graphite as well as chemically bound, in the form of crude oil, natural gas, coal or carbon dioxide. Carbon has been known to mankind since prehistoric times. The use of fire is considered the first chemical process that humans harnessed. As an alloying element, carbon has an enormous impact on the properties of iron and steel. If the carbon content is above 2%, it is cast iron and cannot be forged. If the carbon content is below 2%, the metal is forgeable and is called ferrous metal.

Influencing the carbon content is one of the most important processes in the production of steel. For steels with a low carbon content, carbon can be added to the material by carburising. If there is too much carbon, it can be removed from the alloy by refining.

In general, carbon has a direct influence on hardness and strength, depending on the concentration. However, with increasing content, machinability, forgeability and weldability decrease. The carbon content must be matched to the subsequent use during the manufacturing process.

Carbon can react with other alloying elements such as chromium, vanadium and tungsten and form carbides in the steel structure. The carbides increase the hardness and wear resistance of the steel.

Trivia

The French chemist Lavoisier (1743-1794) ignited a diamond with the help of burning glasses and was able to prove through the combustion that the mineral was crystalline carbon.

Manganese forms very strong compounds with oxygen. In the steel structure, harmful oxygen is bonded in this way. In addition, manganese has a desulphurising effect. This prevents the formation of sulphides. Manganese promotes the formation of austenite because manganese improves the solubility of nitrogen. These properties are of great importance for many stainless steel grades.

Trivia

The English research ship "Challenger" explored the Pacific Ocean in 1873. In trawls, the explorers found many potato-shaped stones, which were manganese. When these tubers were broken open, sharks' teeth were found. Calculations showed that a layer of only 1.5 mm would form in about 1000 years. So these sharks died more than 1.5 million years ago.

In steel production, molybdenum is usually alloyed with other elements such as nickel, chromium and manganese. As an alloying element, it is very important for steel production because it passes on its properties well to the products. High-strength, corrosion- and heat-resistant steels are obtained, as well as acid-resistant stainless steels.

Trivia

Molybdenum is a vital trace element for all organisms, as it is needed for enzyme formation. It is also very important for plants, as it serves to bind nitrogen and reduce nitrate in the root zone.

Nickel is mainly used as an alloying element for stainless steels. It is also added to case-hardened, quenched and tempered and cold-tempered steels to significantly increase toughness. However, it is also used as a coating metal to finish metal objects.

Trivia

Axel Frederic Cronstedt, a student of the great Swedish chemist Brandt, obtained a silvery-white metal when he tried to dissolve copper from an ore. He named it nickel after the mining spirit cupro-nickel. In the Middle Ages, miners considered this ore to be bewitched because it looked like copper ore but did not give off copper.

Niobium is almost always found together with tantalum and because of their chemical similarity, the two elements are almost impossible to separate. For this reason, niobium and tantalum are used together. Both elements form carbide in the steel structure, which makes the steel grades chemically resistant and increases their heat resistance.

Niobium is used as an alloying addition for stainless steels and special stainless steels, as in the pipeline construction of hydrochloric acid production, but also in non-ferrous metals. These alloys have increased strength and toughness even in small quantities.

Niobium forms strong carbides and can thus be used in welding consumables for carbon bonding.It is also used in the field of superconductivity, as a catalyst in the chemical industry, in the manufacture of high-pressure sodium vapour lamps for the outer coating of the glass bulbs and as an electrode material.

As an alloying element, phosphorus only exerts its effect in low-alloy steel with a carbon content of about 0.1%. Then phosphorus increases the strength and also improves the corrosion resistance. In austenitic chromium-nickel steels, phosphorus can increase the yield strength.

Trivia

The German pharmacist Henning Brand discovered phosphorus by chance in 1675. He thought that human urine was suitable for making gold because of its yellow colour. He boiled about 50 buckets of urine until he obtained a wax-like mass.

He did not make gold with it, but after some time the mass began to glow. Parts that were brought into the fresh air caught fire. As it was too expensive to produce, no use could be made of it. Only the German-Swedish pharmacist Scheele was able to produce phosphorus from bones in 1774.

Sulphur is an alloying element which, like lead, is used for the production of free-cutting steels. Sulphur forms inclusions of manganese sulphide in the metal structure, which increase chip breaking. As a result, sulphur-alloyed steels can be machined very well by turning, milling and drilling.

Sulphur has a negative influence on the rust resistance of steels. Due to the influence of moisture, sulphur dioxide and sulphuric acid can form, which attacks the alloy and corrodes it. For this reason, it is necessary to check where steel grades with added sulphur are used.

Trivia

Sulphur was already known 5,000 years before the calendar in China and Egypt as a bleaching agent for textiles, disinfectant and as a medicine. The ancient Greeks used it to preserve wine. In ancient warfare it was used as a fire weapon. The German monk Berthold Schwarz rediscovered black powder, which had already been used by the Chinese in 1044. For a very long time, it was the only known explosive.

The name comes from the Latin word "silex" for silica or flint. It is used in steel production to create thin melts, increase the yield strength, tensile strength and scale resistance of the steel. It also hinders carbide formation.

Trivia

There is a disc of silicon on the moon on which messages from over 70 heads of state have been engraved. This disc was brought to the moon by Neil Armstrong and Buzz Aldrin during the Apollo 11 mission. Unlike other materials, silicon can withstand the enormous temperature fluctuations on the Earth's satellite.

Even by adding the smallest amounts of titanium, a significant increase in toughness and strength can be achieved in the production of steel. In addition, workpieces made of titanium-alloyed steels are more malleable and exhibit greater resistance to intercrystalline corrosion.

Possible uses of titanium steel

- Installations in the offshore industry

- Components for ships

- Chemical plants

- Aerospace

- Turbines and boilers

- Sporting goods

- Medical implants

Vanadium as an alloying element

In the steel structure, vanadium forms vanadium carbide together with carbon, which increases strength, wear resistance and toughness. The addition of vanadium promotes the formation of small grains in the microstructure, making these steels very weldable.

Trivia

Vanadium was discovered twice. First, the Spanish mineralogist Andrés Manuel del Rio discovered it in Mexico in 1801. He named the new element "panchrome" and later erythronium. Unfortunately, his discovery was forgotten because he was convinced by a chemist that it was only contaminated chromium.

30 years later, vanadium was rediscovered by Nils Gabriel Selfstöm, who named the element "Freyja" after the Nordic goddess of beauty because of the variety of colours. In old lore from Iceland, Freyja bears the epithet Vanadis.

The best known is the use of tungsten in light bulbs. It is used in many industries because this metal has an enormously high melting point and is very hard. In metallurgy, tungsten is an important alloying element, but it can influence the properties of steel both positively and negatively.

Tungsten reacts with carbon during steel production to form tungsten carbide, which makes this steel very hard and tough. Tungsten has a negative effect on scaling resistance.

See also

Technical Gases

Technical gases: Use, properties and applications of speciality gases in the processing of sheet metal and in the manufacture of welded assemblies

Read more