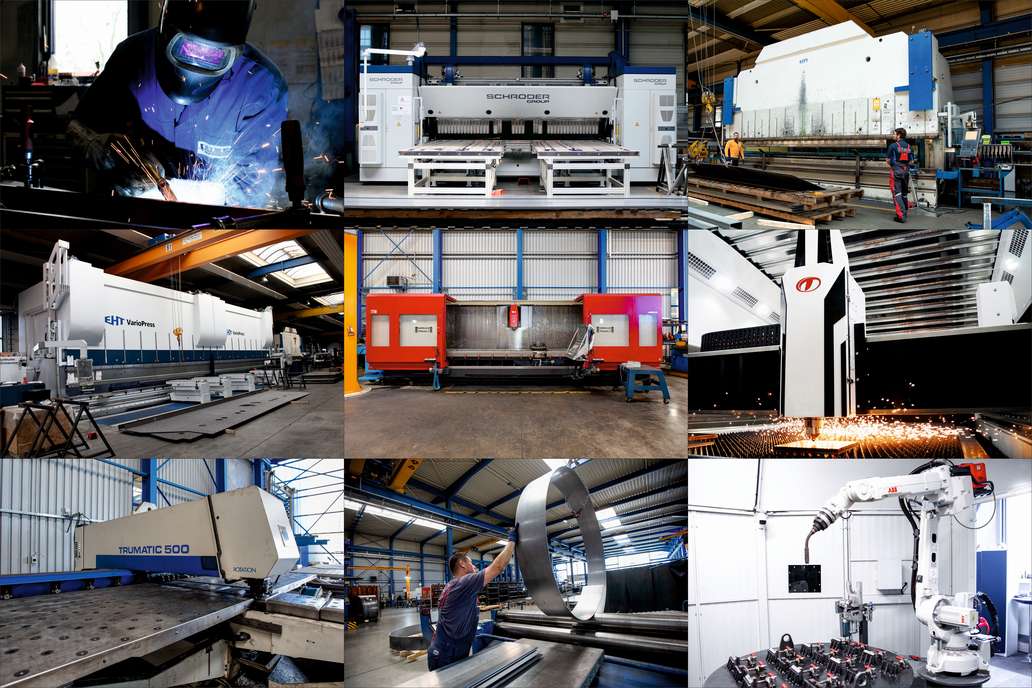

Machine List

Laser Cutting

Plate metal thickness 0,5 mm to 25 mm | working area 16,000 x 4,000 mm | Cutting of plate metal made of steel, stainless steel and aluminium | Laser cutting including chamfers up to 45°

- 4 Laser cutting machines

- CoolLine & BrightLine - cutting process

Fiber Laser Cutting

Powerful cutting of steel and stainless steel up to 25 mm thickness | Aluminium laser cutting up to 25 mm thickness | Working area 6,000 x 2,000 mm

- Very high performance enables faster cutting speeds

- Laser parts with high dimensional accuracy

Plate Metal Bending

Up to 16,000 mm bending length | sheet thickness max. 25 mm on full length | processing of steel, stainless steel, aluminium as well as high-strength and wear-resistant steel grades

- 6 press brakes

- Machining of large and small parts

Swing Beam Bending

Efficient production of complex bent parts using the up-down technique | Scratch-free processing of stainless steel plates | High automation and short set-up times

- Bending of plate metal up to 4,000 mm width

- Forming of plate metal up to 4 mm thickness

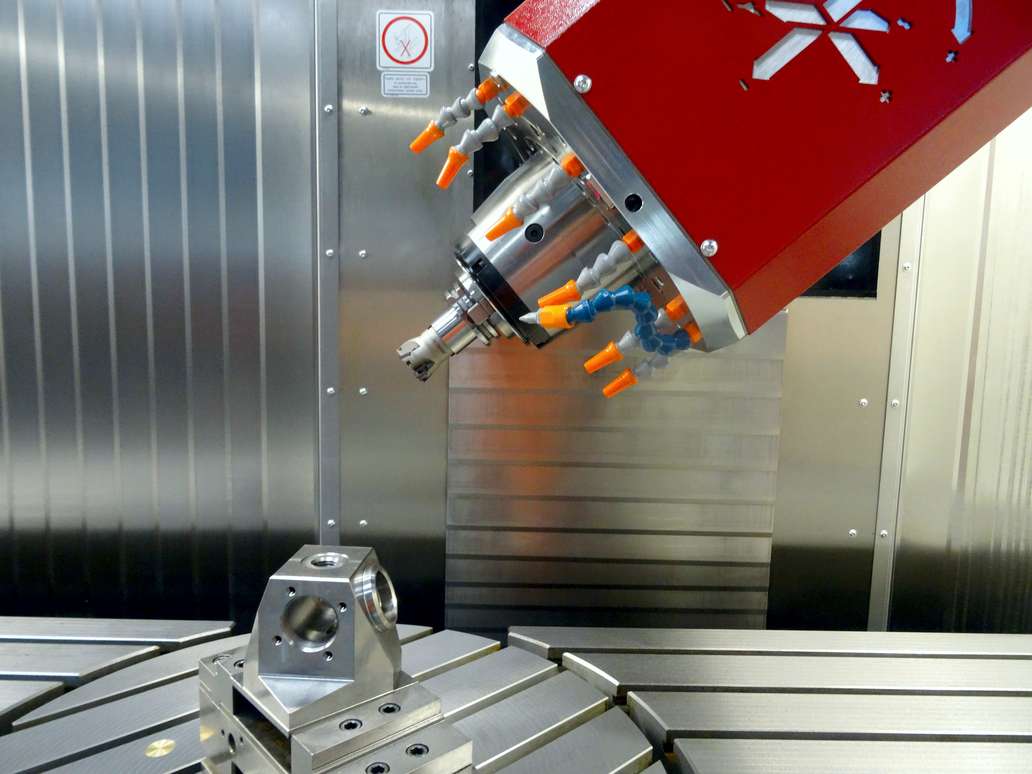

Milling

Machining of large, bulky milled parts up to 4,200 mm in length | Production of chamfers, pockets, drill holes, threads and much more | Very high precision

- 3D and 5D - processing

- 2 Modern machine centers

Punching & Nibbling

Punching and nibbling in sheet metal up to 8,000 x 1,600 mm | Production of recesses, threads, louvres and beads | Short set-up times due to automatic tool change

- Steel up to 6 mm thickness

- Stainless steel up to 4 mm

Shearing

Fast, straight plate cuts | Cost-effective processing

- XXL- scissors up to for blanks up to 8,100 mm length

- Another pair of scissors up to 3,050 mm

- Maximum sheet thickness up to 8 mm

Roll Bending

Roll bending of plate metal up to a width of 2,500 mm | The smallest possible diameter is 260 mm | Manufacture of tubes, half-shells, joints and rings

- Steel and aluminium up to 6 mm thickness

- Processing of rustproof steel up to 4 mm

Breaking Edges

Breaking edges, deburring and rounding | Increase in quality and dimensional accuracy | Processed parts can be better assembled

- Maximum work piece width of 1,600 mm

- Material thickness 1 - 100 mm

Barrelling

Barrelling of small parts up to 150 x 150 mm | Removal of dirt, slag, scale and grease | Deburring and removal of scratches

- 2 vibratory finishing machines with a capacity of 300 l each

- Residue-free drying through vibration round dryer

Robot Welding

Welded assemblies in serial production | High accuracy of position and path repetition | Consistently high quality

- Working area of 1,450 x 1,000 mm

- Assemblies up to 750 kg weight

Welding Equipment

Welding department with modern technologies | Application of all common welding methods | Welded assemblies up to 50 Metric Tons weight

- MIG / MAG and TIG welding

- Spot and stud welding